Cross-linked polyethylene PE XPE / xlpe Foam

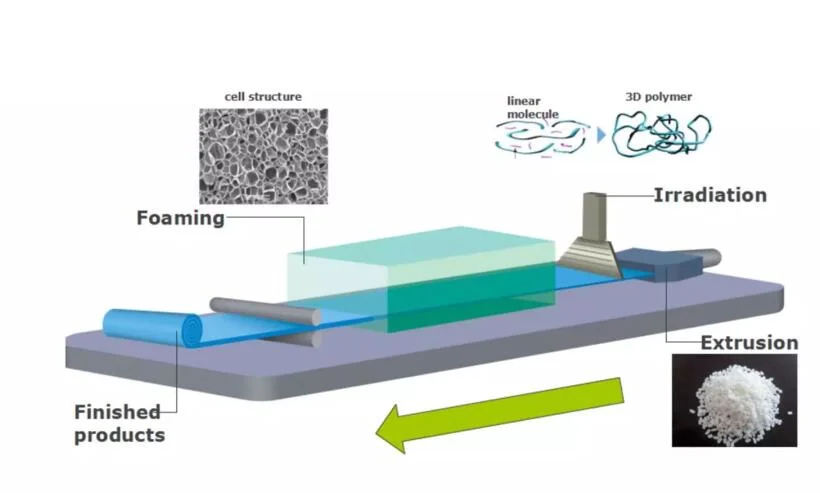

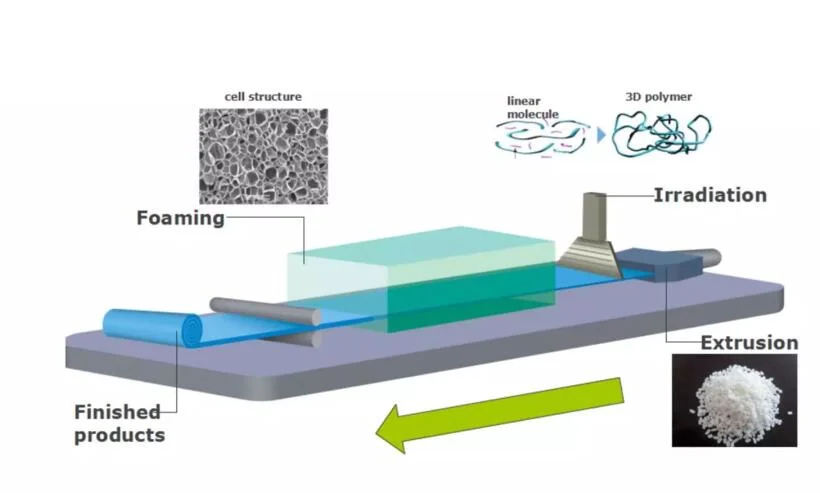

IXPE foam is produced by compounding PE with some special padding and foaming material,then cross linking by irradiation and foaming which is considered as polymer material, expect the property of XPE, the IXPE has better property than the XPE foam: Its surface is much more smooth, the obturator foramen is much more well-proportioned and detailed, and its physical property is much better, too. Because of its environmental property, it is extensively used in food packing daily leisure use and medical instruments.

Technical Index

Fetures

Good impact absorptionNon toxic and odourless ESD foamsLightweight

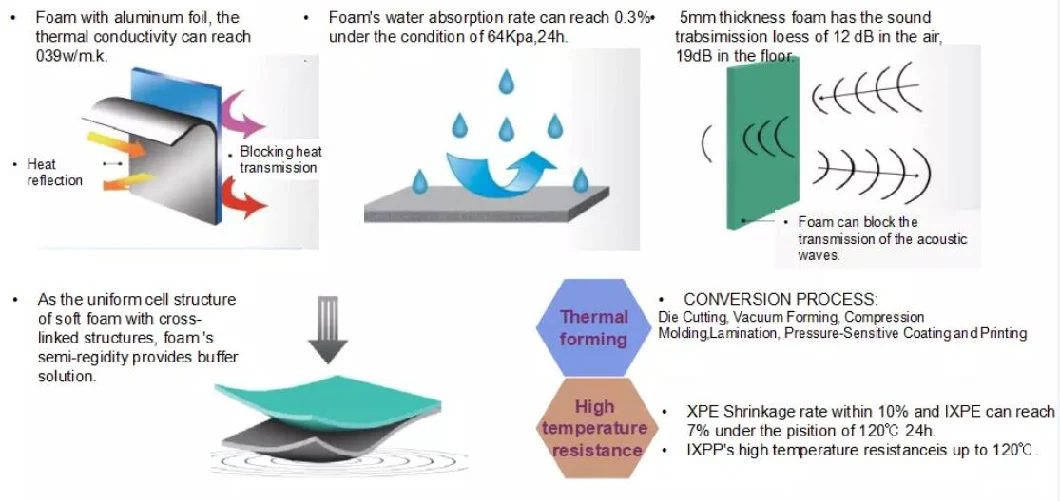

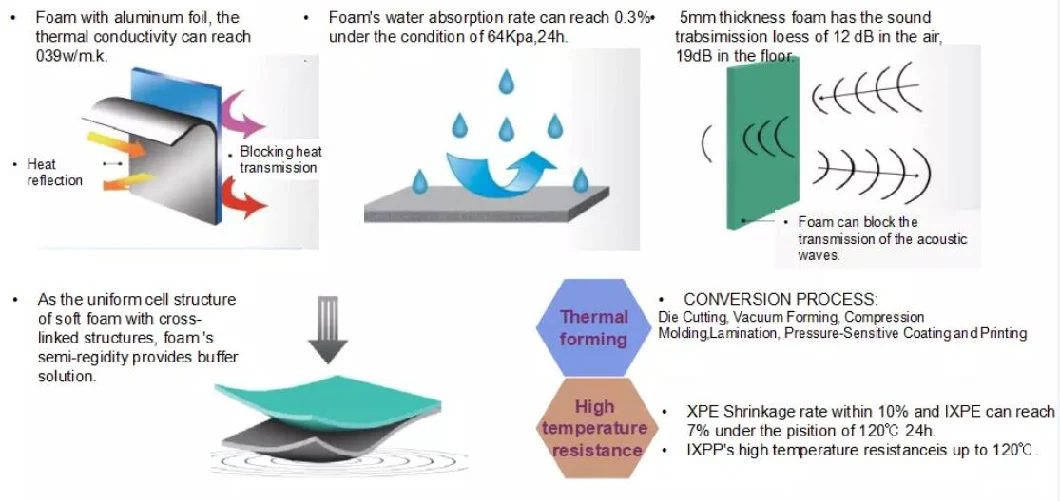

Superior Compression/Tension characteristicsThermal absorptionSound absorption

No smelling, non-toxic: Use ecologic material, RoHS approval

Soft and comfortable: Flexible with good elastic, stay the shape soon after press

Dampproof and waterproof: Closed cross linked structure

Heat insulation: Closed cross linked structure, keep warm

Anti slip: Embossed surface

Light and portable: About 500g/PCS

Durable: Good elastic and closed cross linked structure

Product Details

Product Packaging & Delivery

Application

IXPE foam is produced by compounding PE with some special padding and foaming material,then cross linking by irradiation and foaming which is considered as polymer material, expect the property of XPE, the IXPE has better property than the XPE foam: Its surface is much more smooth, the obturator foramen is much more well-proportioned and detailed, and its physical property is much better, too. Because of its environmental property, it is extensively used in food packing daily leisure use and medical instruments.

Technical Index

| Index Sheet | |||||||||||

| Density (kg/m3) | 300±40 | 200±30 | 125±15 | 100±10 | 66.7±8 | 50±6 | 40±4 | 33.3±3 | 28.6±3 | 26±3 | |

| Shore Hardnes (°) | 65~75 | 60~70 | 50~60 | 45~50 | 35~45 | 30~35 | 25~30 | 18~25 | 13~18 | 13~18 | |

| Tensile Stength(MPa) | T | ≥1.4 | ≥1.3 | ≥0.9 | ≥0.7 | ≥0.5 | ≥0.35 | ≥0.3 | ≥0.2 | ≥0.15 | ≥0.15 |

| L | ≥1.6 | ≥1.5 | ≥1.0 | ≥0.8 | ≥0.6 | ≥0.38 | ≥0.35 | ≥0.25 | ≥0.2 | ≥0.2 | |

| Elongation (%) | T | ≥150 | ≥130 | ≥125 | ≥110 | ≥100 | ≥80 | ≥80 | ≥80 | ≥70 | ≥70 |

| L | ≥170 | ≥150 | ≥125 | ≥120 | ≥110 | ≥90 | ≥90 | ≥90 | ≥80 | ≥80 | |

| Tearing Stength (KN/m) | T | ≥11 | ≥9 | ≥8 | ≥6 | ≥4 | ≥2.5 | ≥2 | ≥1.5 | ≥1.3 | ≥1.3 |

| L | ≥11 | ≥9 | ≥8 | ≥6 | ≥4 | ≥2.5 | ≥2 | ≥1.2 | ≥1.2 | ≥1.2 | |

| Compressed Distortions (%)23ºC±2ºC,22h | ≤2 | ≤2 | ≤3 | ≤5 | ≤7 | ≤8 | ≤9 | ≤10 | ≤11 | ≤11 | |

Fetures

Good impact absorptionNon toxic and odourless ESD foamsLightweight

Superior Compression/Tension characteristicsThermal absorptionSound absorption

No smelling, non-toxic: Use ecologic material, RoHS approval

Soft and comfortable: Flexible with good elastic, stay the shape soon after press

Dampproof and waterproof: Closed cross linked structure

Heat insulation: Closed cross linked structure, keep warm

Anti slip: Embossed surface

Light and portable: About 500g/PCS

Durable: Good elastic and closed cross linked structure

Product Details

| Regular Dimension | Can be customized as requirement | |||

| Thickness&Density Single fold | Thickness | 2-10mm | Density | 100-240kg/m3 |

| Thickness&Density Muti-fold | Thickness | 10-100mm | Density | 28-100kg/m3 |

Product Packaging & Delivery

| Foam status | sheets and blocks,rolls |

| Package Details | packing as request or common packing with PE bag. |

| Delivery Details | 3-6 Work Days since the date of order |

| Process services | Die Cutting,Lamination Adhesive ,Sheeting, Perforating & Skiving |

Application

| Building and Construction |

| Automotive |

| Sports & Leisure |

| Transit Packaging |

| Sealing Insulation Damping |

| Equestrian foam and rubber tiles |

| Archery targets Canoe buoyancy & seating |

| Body protection |