60mm non crosslinked expanded Polyethylene/EPE Foam Sheet Making Machine

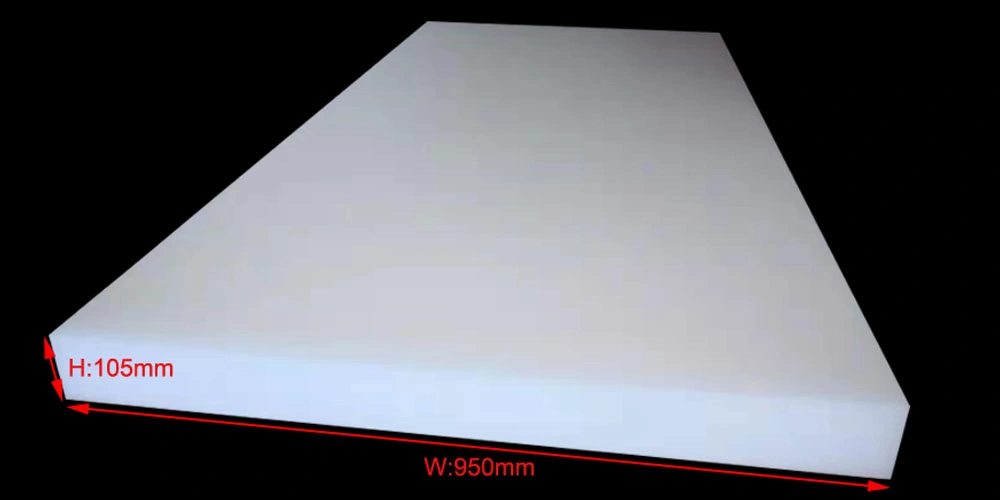

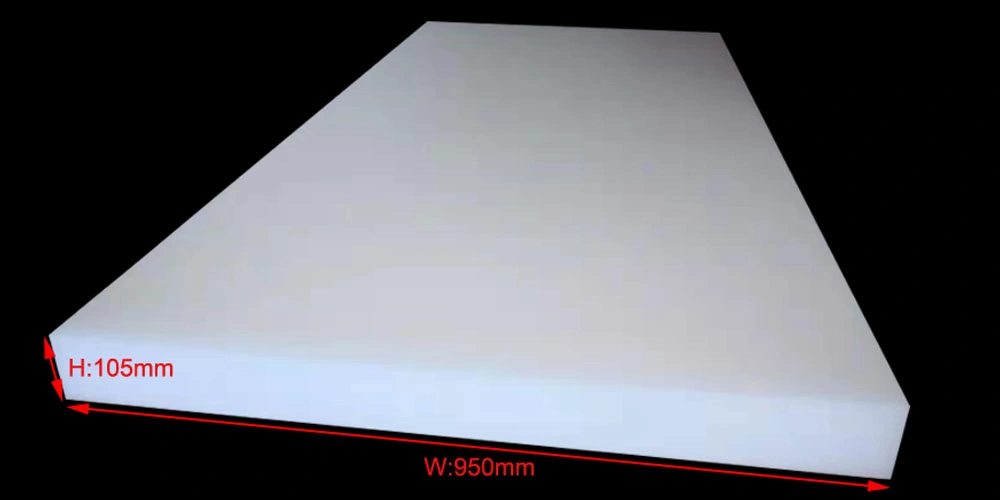

Single-layer EPE foam thick plank making machine, also called EPE foam making machine directly extruding 40mm~105mm thickness EPE foam planks. which reduces the multiple thickening process of the bonded EPE board. Increased production efficiency, saved production costs, and has a very high safety factor.

Advantages of Our EPE foam machine:

1.) Single-layer thickness: 40mm~105mm, Density:18kg/m3~64kg/m3;

2.) 4 workers in total for the complete process from material feeding to the EPE foam board curing;

3.) Sharing 100% domestic market;

4.) Board storing area saving 30-40%.

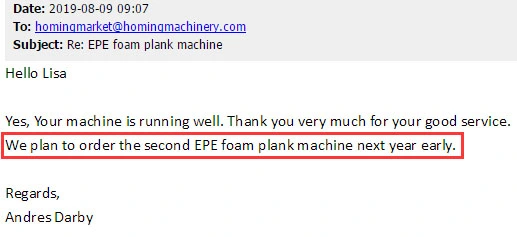

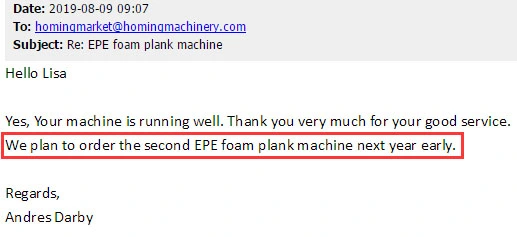

Customers feedback as following:

From Peyman Roshan

From Andres Darby

EPE foam making machine photo

Parameters

What's EPE foam plank?

Physical Performances of EPE foam

1. Strong excellent tensile and tear properties

2. Flexible-bends without breaks or tears

3. Good resilient- recovers from compressions and impacts.

4. Non-toxic and odorless

5. Moisture-proof and chemical resistance

6. Insulation- low thermal conductivity

7. Easily to be laminated- bonds to itself or other substrates

Applications

EPE foam plank producing process

Shipping

Certifications

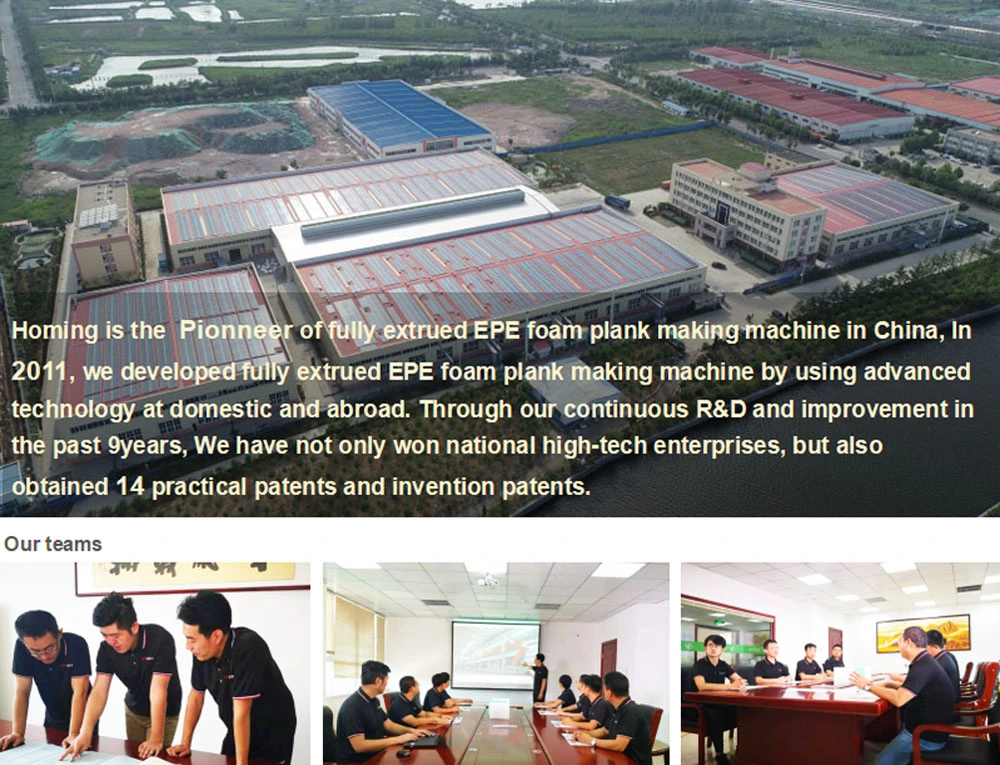

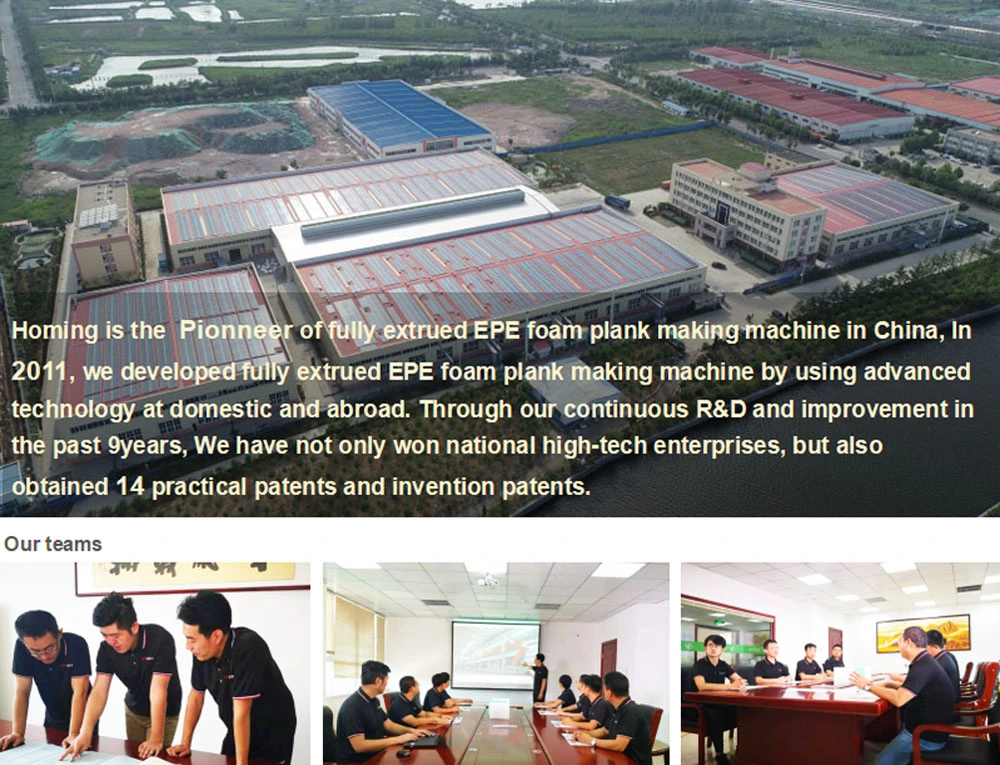

About Homing

FAQ

Q1: What's your EPE foam machine advantage?

A1: Saving producing cost, and safer without bonding process;

Q2: How many machines you have sold?

A2: Sharing 100% domestic market;

Q3: Can I see the running machine in your factory?

A3: Yes;

Q4: What's your warranty policy?

A4: Guarantee for 12 months;

Q5: What are your terms of payment?

A5: T/T, L/C.

Q6: Where's your factory located?

A6: In Qingdao city, China

Please don't hesitate to contact us for more details!

Single-layer EPE foam thick plank making machine, also called EPE foam making machine directly extruding 40mm~105mm thickness EPE foam planks. which reduces the multiple thickening process of the bonded EPE board. Increased production efficiency, saved production costs, and has a very high safety factor.

Advantages of Our EPE foam machine:

1.) Single-layer thickness: 40mm~105mm, Density:18kg/m3~64kg/m3;

2.) 4 workers in total for the complete process from material feeding to the EPE foam board curing;

3.) Sharing 100% domestic market;

4.) Board storing area saving 30-40%.

Customers feedback as following:

From Peyman Roshan

From Andres Darby

EPE foam making machine photo

Parameters

EPE foam plank | Thickness | 40mm~105mm ± 2mm |

Density | 18~64kg/m3 | |

Width(max) | 1,000mm | |

Length | 9,000mm | |

EPE foam machine | Capacity | 330kg/hr±10% |

Electric power(consumption) | 135-150kw/h | |

Machine size | 50mx10mx3.2m |

What's EPE foam plank?

The Non-crossed Expanded Polyethylene Foam Plank(EPE) is an Eco-friendly and advanced material in the world for mattress making, inner packaging, DIY toys. It is consists of numerous and independent bubbles produced by low-density polyethylene(LDPE) resin physical foamed. EPE Plank overcomes the shortcomings of common plate's brittle and deformation. What's more, it also has a lot of outstanding functions, such as good cushioning, high seismic capacity, insulation, shockproof, anti-corrosion, soundproof and recyclable. Even fold 180 degrees and will not be broken.

Physical Performances of EPE foam

1. Strong excellent tensile and tear properties

2. Flexible-bends without breaks or tears

3. Good resilient- recovers from compressions and impacts.

4. Non-toxic and odorless

5. Moisture-proof and chemical resistance

6. Insulation- low thermal conductivity

7. Easily to be laminated- bonds to itself or other substrates

Applications

EPE foam plank producing process

Shipping

Certifications

About Homing

FAQ

Q1: What's your EPE foam machine advantage?

A1: Saving producing cost, and safer without bonding process;

Q2: How many machines you have sold?

A2: Sharing 100% domestic market;

Q3: Can I see the running machine in your factory?

A3: Yes;

Q4: What's your warranty policy?

A4: Guarantee for 12 months;

Q5: What are your terms of payment?

A5: T/T, L/C.

Q6: Where's your factory located?

A6: In Qingdao city, China

Please don't hesitate to contact us for more details!