Automatic PE closed cell foam sheet extruder manufacturer from China

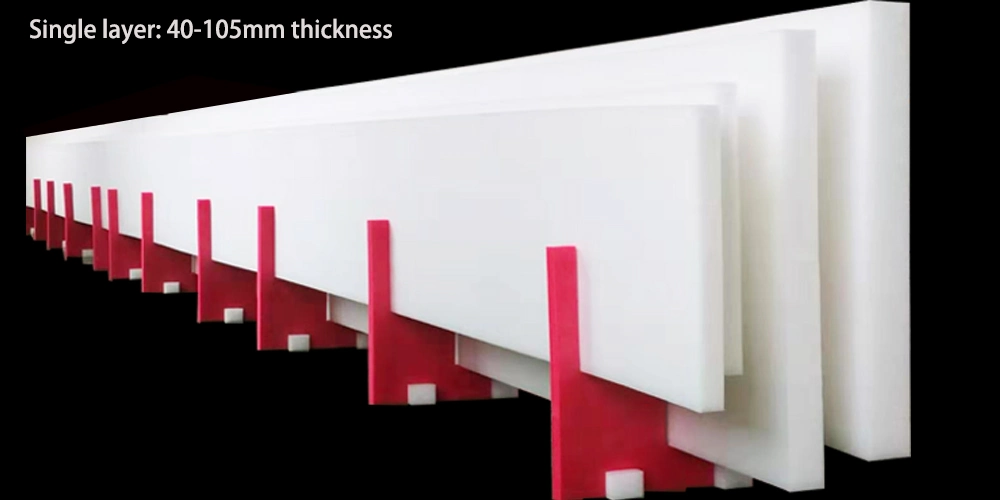

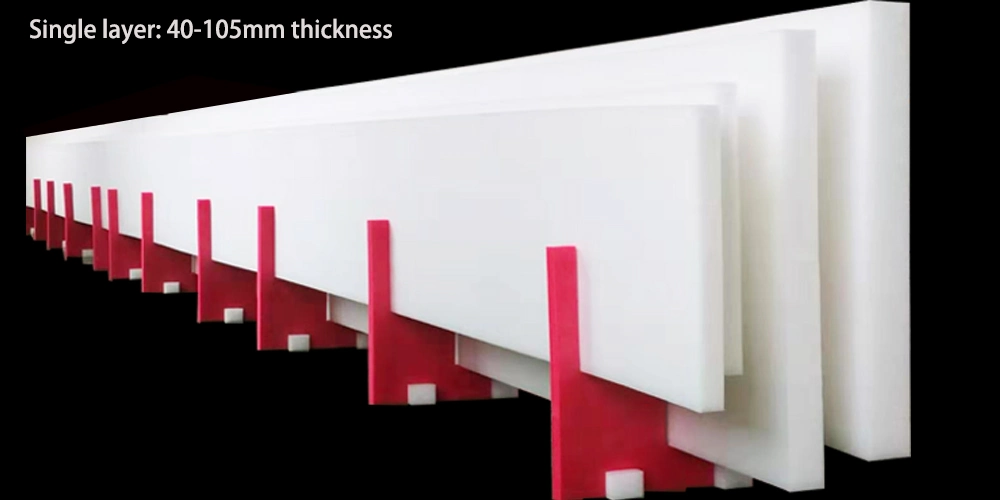

Our EPE foam sheet extrusion machine, making 40mm~100mm thickness EPE foam planks directly, without lamination process, Increased production efficiency, saved production costs and has a very high safety factor.

Advantages of Our EPE foam machine:

1.) Single-layer thickness: 40mm~100mm, Density:18kg/m3~64kg/m3;

2.) 3workers in total for the complete process from material feeding to the EPE foam board curing;

3.) Sharing 100% domestic market;

4.) Board storing area saving 30-40%.

Customers feedback as following:

From Peyman Roshan

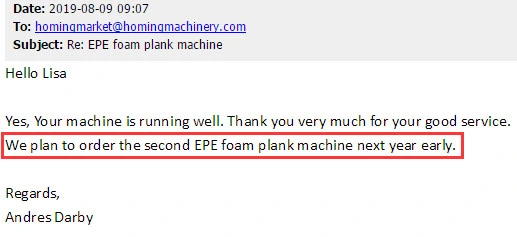

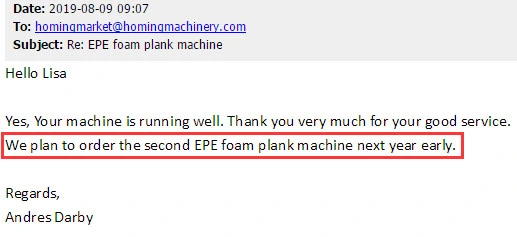

From Andres Darby

EPE foam making machine photo

Parameters

What's EPE foam plank?

Physical Performances of EPE foam

1. Strong excellent tensile and tear properties

2. Flexible-bends without breaks or tears

3. Good resilient- recovers from compressions and impacts.

4. Non-toxic and odorless

5. Moisture-proof and chemical resistance

6. Insulation- low thermal conductivity

7. Easily to be laminated- bonds to itself or other substrates

Applications

EPE foam plank producing process

Shipping

Certifications

About Homing

Homing located in Qingdao, near seaport. Founded in 2011. It's the professional manufacturer for EPE foam machine, pe foam sheet machine, EPE foam sheet production line, PE foam sheet extrusion line, EPE foam sheet making machine, EPE foam sheet mattress making machine, PE foam sheet production line, PE foam sheet extruder, polyethylene foam sheet extrusion machine, polyethylene sheet rolling machine, EPE foam sheet making machine, EPE foam sheet extruding machine, and EPE recycling machine.

So if you wanna know EPE foam sheet manufacturing process, Epe foam machine manufacturing process, Epe foam manufacturing project. please don't hesitate to contact us, Will give you the EPE foam turn-key project.

FAQ

Q1: What's your EPE foam machine advantage?

A1: Saving producing cost, and safer without bonding process;

Q2: How many machines you have sold?

A2: Sharing 100% domestic market;

Q3: Can I see the running machine in your factory?

A3: Yes;

Q4: What's your warranty policy?

A4: Guarantee for 12 months;

Q5: What are your terms of payment?

A5: T/T, L/C.

Q6: Where's your factory located?

A6: In Qingdao city, China

Please don't hesitate to contact us for more details!

Our EPE foam sheet extrusion machine, making 40mm~100mm thickness EPE foam planks directly, without lamination process, Increased production efficiency, saved production costs and has a very high safety factor.

Advantages of Our EPE foam machine:

1.) Single-layer thickness: 40mm~100mm, Density:18kg/m3~64kg/m3;

2.) 3workers in total for the complete process from material feeding to the EPE foam board curing;

3.) Sharing 100% domestic market;

4.) Board storing area saving 30-40%.

Customers feedback as following:

From Peyman Roshan

From Andres Darby

EPE foam making machine photo

Parameters

EPE foam plank | Thickness | 40mm~100mm |

Density | 18~64kg/m3 | |

Width(max) | 1,000mm | |

Length | 9,000mm | |

EPE foam machine | Capacity | 330kg/hr±10% |

Electric power(consumption) | 135-150kw/h | |

Machine size | 50mx10mx3.2m |

What's EPE foam plank?

The Non-crossed Expanded Polyethylene Foam Plank(EPE) is an Eco-friendly and advanced material in the world for mattress making, inner packaging, DIY toys. It is consists of numerous and independent bubbles produced by low-density polyethylene(LDPE) resin physical foamed. EPE Plank overcomes the shortcomings of common plate's brittle and deformation. What's more, it also has a lot of outstanding functions, such as good cushioning, high seismic capacity, insulation, shockproof, anti-corrosion, soundproof and recyclable. Even fold 180 degrees and will not be broken.

Physical Performances of EPE foam

1. Strong excellent tensile and tear properties

2. Flexible-bends without breaks or tears

3. Good resilient- recovers from compressions and impacts.

4. Non-toxic and odorless

5. Moisture-proof and chemical resistance

6. Insulation- low thermal conductivity

7. Easily to be laminated- bonds to itself or other substrates

Applications

EPE foam plank producing process

Shipping

Certifications

About Homing

Homing located in Qingdao, near seaport. Founded in 2011. It's the professional manufacturer for EPE foam machine, pe foam sheet machine, EPE foam sheet production line, PE foam sheet extrusion line, EPE foam sheet making machine, EPE foam sheet mattress making machine, PE foam sheet production line, PE foam sheet extruder, polyethylene foam sheet extrusion machine, polyethylene sheet rolling machine, EPE foam sheet making machine, EPE foam sheet extruding machine, and EPE recycling machine.

So if you wanna know EPE foam sheet manufacturing process, Epe foam machine manufacturing process, Epe foam manufacturing project. please don't hesitate to contact us, Will give you the EPE foam turn-key project.

FAQ

Q1: What's your EPE foam machine advantage?

A1: Saving producing cost, and safer without bonding process;

Q2: How many machines you have sold?

A2: Sharing 100% domestic market;

Q3: Can I see the running machine in your factory?

A3: Yes;

Q4: What's your warranty policy?

A4: Guarantee for 12 months;

Q5: What are your terms of payment?

A5: T/T, L/C.

Q6: Where's your factory located?

A6: In Qingdao city, China

Please don't hesitate to contact us for more details!